Cornerstone Automation helped automate a patented sortation process invented for LEED compliance documentation making it more sustainable and efficient.

Richard S. Burns & Company Inc. is a progressive recycling company that processes thousands of tons of construction waste and materials per day. In response to requirements for LEED (Leadership in Energy and Environmental Design) Certification, they invented a solution to aid their customers in having the proper documentation. The brand new patented solution they invented is a sortation system that tracks materials and collects the weights of full individual bins of sorted commodities for individual customers.

The recycling company needed automated controls to dump, photograph, and weigh the materials, tabulate the data by recycling material type, and communicate the data back into the company’s SQL database. Cornerstone Automation was contracted to assist with the industrial controls and software required for automating the sortation line.

In the past, the LEED reporting information provided to customers wasn’t as accurate and the sortation was done manually which was much more inconvenient. Dumpsters shared between on-site contractors made it almost impossible to determine which specific commodities Company A or Company B recycled from the job, and processing the dumpsters, sorting the material into rolling bins, weighing them, and recording the data manually left a lot of room for error.

“As our line’s complexity grew, we realized we needed better and more accurate controls, which led us to find an integrator with expertise in industrial components and control systems. The Cornerstone team didn’t seem to be bothered by the size of the project and they had great suggestions. Their team is very knowledgeable and has impressive experience,” said Rob Rudloff, IT Specialist at Richard S. Burns & Company Inc. “We made a lot of changes based on what Cornerstone suggested moving forward. They had a lot of experience on the automation side, and brought many resources to the table.”

The Cornerstone engineers had to anticipate errors and then develop code to respond accordingly to the possibility of specific errors. They were able to immediately identify where potential issues could be to offer solutions from a controls and component selection perspective. The engineers relied on their extensive experience interfacing with real-world industrial automation complexities and managing common issues in machine-building.

“We had to put a lot of code in to make exceptions for when specific things happen and to create ways to bypass or retry different steps in sequence, under different conditions,” said lead engineer, Nathan Ferrin.

With the new system, contractors or subcontractors utilizing the recycling company’s services at a job site use the barcoded Tommy Carts® to differentiate each company’s waste materials from the job site at the recycling facility. There are groups of up to 20 barcoded carts coming in from each individual customer that are associated with a ticket, and each ticket is a group of carts associated with a customer site. Each recycled commodity is weighed, and that data is reported back for each company’s LEED documentation.

Dave Curry, IT Engineer for Richard S. Burns & Company Inc stated, “I would say that the software that Cornerstone Automation wrote for the panel is spot on. We don’t have bugs, It was very, very reliable.”

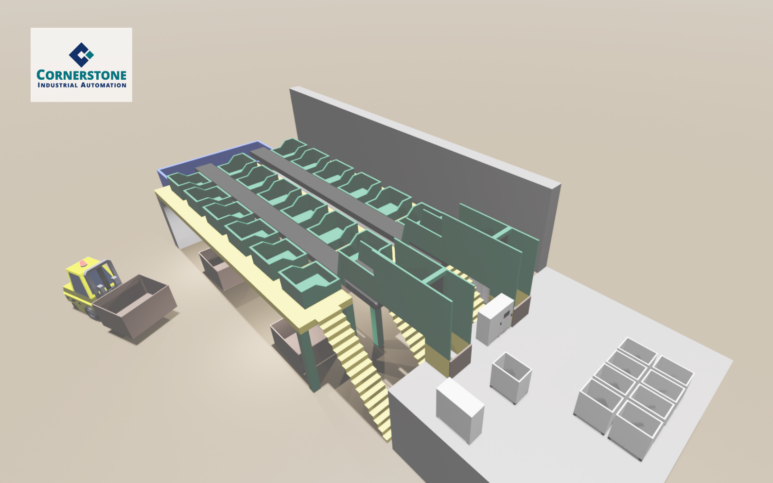

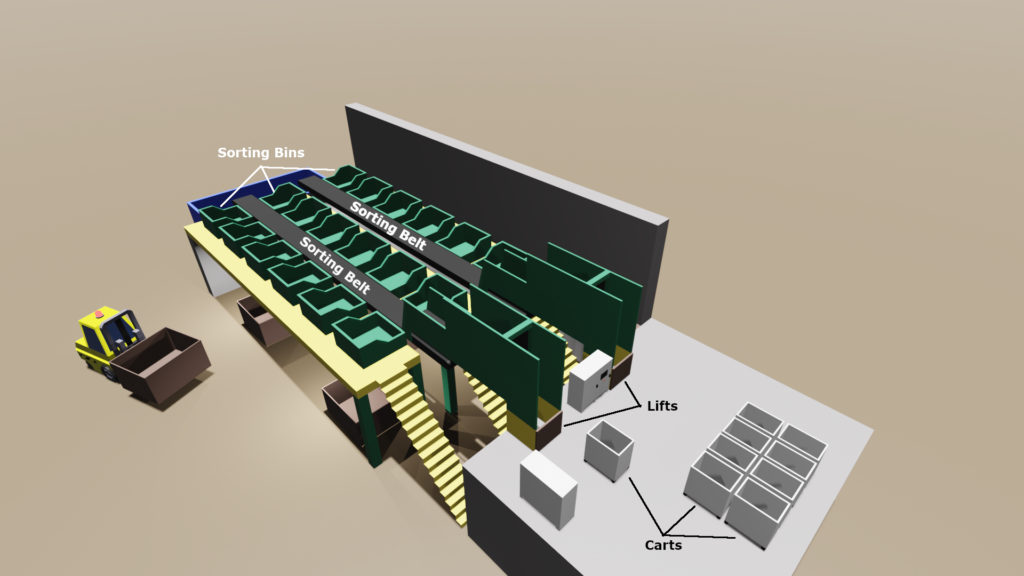

How Does it Work?

The very first step in the process is the operator rolling the cart onto a platform where it’s attached to a hydraulic lift. The barcode is scanned, and either validated as part of the ticket or if it’s the first cart from a new ticket, it pulls the ticket information. Commanded by the PLC, the hydraulic lift raises the cart up, and a rotational hydraulic cylinder dumps it upside down onto the conveyor.

Once the commodity is dumped, the material is spread out on that conveyor and photographed. When it moves onto the sorting belt it’s manually sorted and placed into one of 12 user-adjustable bins based on the commodities that they have that day. For example, operators that have an excessive amount of drywall can use the HMI screen to allocate four bins for just drywall.

The bins have push buttons that an operator engages to indicate that it needs to be emptied. The forklift operator is notified through a tablet PC HMI that is attached. The operator uses the HMI to “acknowledge dump,” which sends a request for the bin to open. The bins have a door on the bottom that slides open to dump its contents into a lower bin that is taken away to the bulk storage.

After the product is sorted, a total is taken for the amount of material that was in all of the bins, and the weight is tared. Since bins may fill up in the middle of a ticket, or alternatively may be only partially filled at the end of a ticket, the operator has the ability to empty them asynchronously into rolling bins that are below them. Essentially there are bin weights and then there are commodity totals for each ticket and they’re tracked independently.

When the last cart dumps and runs out to the end of the belt, the commodities that were collected during that ticket are totaled, and that information is sent back to the SQL server where the recycling company continues to process it, and use it to generate their LEEDS reports.

This innovative solution is the product of a synergistic partnership between Richard S. Burns & Company Inc, and Cornerstone Automation. The recycling company had internal engineers and IT experts that contributed to this solution, but they needed Cornerstone Automation’s expertise in programming industrial automation controls, interfacing with digital electro-mechanical feedback devices such as encoders, and communicating the appropriate data back to the SQL database. The two companies maintained excellent communication throughout the process, and engineers on both sides worked together to dial in the final solution, and successfully complete the project.

For more information on how to utilize Richard S. Burns & Company’s Tommy Carts® solution visit their website at Richard S. Burns & Company Inc.

For assistance with developing unique industrial automation solutions contact Cornerstone Automation.